top of page

PROFWARE SYSTEMS

Powerful software for industrial applications

The platform offers an advanced processing layer on top of SCADA/DCS while also capable to operate as a standalone control centre. It extends traditional supervisory control with customised business logic capabilities and powerful data analytics all integrated into OT environment.

ARTData can be applied in a number of use cases including idustrial ML applications, model based prediction and alerts, real-time system identification, parameters scheduling for batch processes, procedural automation and IIoT sensors data processing.

Bringing modern software to OT

web-based user-friendly interface, integrated SQL and Python, custom plugins, version control.

Speaks native with SCADA & DCS practitioners

scan-time based computation, runtime redundancy, tag-based address space, industrial protocols.

Empowered process control

regulatory and sequence control, advanced analytics and ML, embedded time-series data.

Integrated HMI

dashboard-style interactive visualisation and control.

Real-time and Time-series

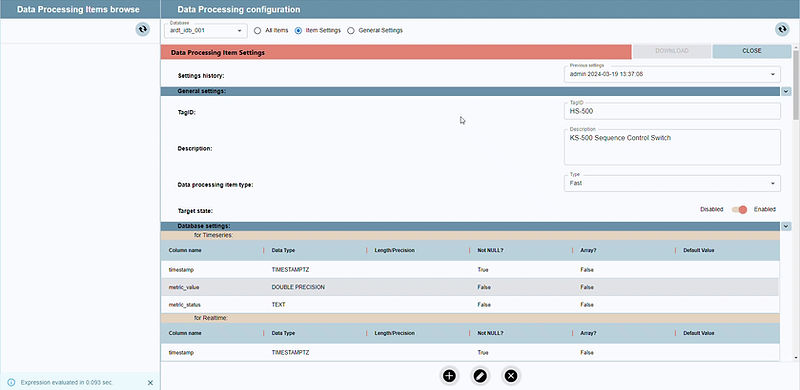

ARTData creates a fusion between current-time and historical data, making both available for control, analytics and visualisation. Configurable database allows to setup project specific headers and data types, while multi-table setup allows to distribute data and processing load.

Python & SQL Data Processing

Python and SQL, the two most widely used programming languages for ML applications, complement each other allowing fast retrieval and flexible processing when working with data. Featuring tag based address space, tags dependencies tree visualisation, version control and pre-download calculations check-up, the platform creates seamless process control configuration experience.

Industrial communication protocol

Acting as an OPC UA client, ARTData can retrieve and send data with a number of systems and devices respecting specified data types and update frequency.

OT & Edge oriented

Edge data processing can provide tangible benefits to a business through balancing data streams and making computation results available for end user in remote locations where data is collected. In Industrial OT area specifically, Edge processing can bring important advantages on top of cloud-only architecture:

Increased system reliability and availability with no dependency on quality of communication with the cloud;

Integration into tightly controlled network within OT environment without compromising cybersecurity;

Integration with control layer to enhance process monitoring and control by generating unique process variables and applying advanced data processing techniques;

option for inbuilt redundancy and mitigation of single point failure at Cloud level;

reduced latency close to real-time classic instrumentation;

building up trust and ownership in end user as the system is operated and maintained locally.

bottom of page